Preparing for new legislation

So what does all this mean for future labeling requirements of EV batteries? First and foremost, label materials must meet high standards for durability and perform under harsh conditions. In the future, as legislation establishes mandatory sustainability requirements and end-of-life battery management, OEMs must consider intelligent labeling solutions that enable a second-life.

There is a growing need for labeling solutions that meet strict qualification requirements and legislation – presenting an exciting opportunity for the automotive industry.

Building the foundation: Sustainable pressure-sensitive materials for EV batteries

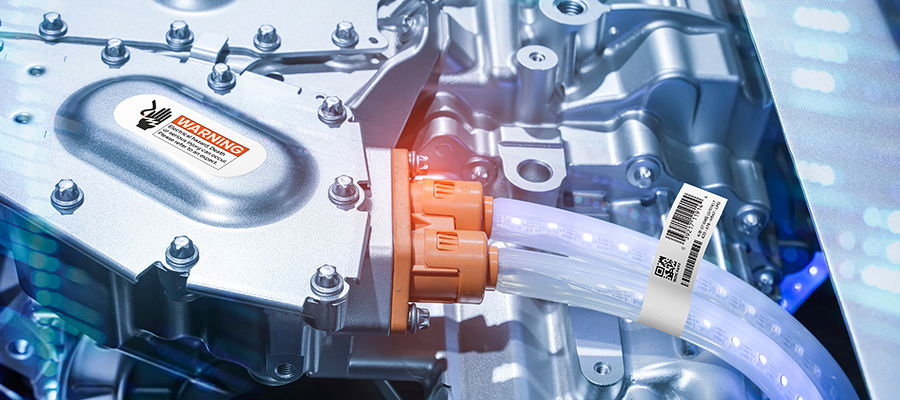

As the EV battery industry grows, new specifications are coming to light, resulting in the need for even more pressure-sensitive materials. The industry has identified additional labeling requirements that ensure safety, insulation and readability for EV battery components, such as:

Self-extinguishing facestocks and adhesives with slow-burning materials

Materials with greater dielectric strength that offer better electrical insulation

High shear adhesives that can withstand mechanical stressors such as abrasions and punching

Greater resistance to acetone, xylene and other harsh chemicals that ensure the visibility of printed information

As we work towards supplying our customers with solutions that meet these standards, we cannot overlook the environmental impact of our materials. Our facestocks with PET contain up to 70% of recycled content, and our rPET liners contain 30% recycled content. Connecting pressure-sensitive materials with sustainability builds the label's foundation, but bridging the physical with the digital is the key to keeping EV batteries in circulation as long as possible.

Connect the physical with the digital using RFID

Through the IoT – the internet of things – EV battery components connect with the online ecosystem, unlocking the potential for a new second-life battery supply. Inserting RFID labeling technology into standard label constructs equips labels with added digital capabilities that offer vast data storage capabilities from asset tracking, to supply chain transparency and more.

RFID tags connect to our product cloud Atma.io, where it's assigned a unique digital ID – providing end-to-end transparency by recording all events associated with that product. For example, battery cells can be successfully tracked throughout their lifetime, thus satisfying the European Commission's DPP goals. RFID enabled labels will become increasingly important in supporting a circular economy and be crucial to the success of future sustainable product initiatives.